Equipping the best and most efficient blade, which touches the roll in subject, helps keep fine quality in your products, and keep Doctor perform well.

We should select the best Doctor Blade, according to your factory’s environmental conditions on which Doctor is implemented, including operational conditions and types of contaminants to be removed.

Doctor Blade, as the one and only to touch the roll of your product, is created from materials of selective high quality with high level of delicacy.

As an expendable item, its cycle cost and delivery speed also should be considered upon your choice of blade and material.

We, with accumulated expertise and experience, will propose the best and yet practical Doctor Blade for you.

Doctor Blade

Doctor Blade will be designed, taking into consideration the material of the subject roll and the environment that Doctor is used for, from the various types we could offer.

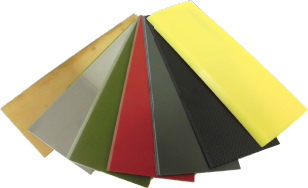

We offer a wide range of materials and forms in addition to the choice of metallic and resin for the best Doctor Blade for your usage.

Please feel free to contact us for selection of Doctor Blade.

Stainless steel can use for various purposes, ranging from martensitic type, which features high hardness, to austenitic type, which has high corrosion resistance.

■JIS Steel Grade (and equivalents)

SUS420,SUS304,SUS316

Hardness: approx. Hs65 ~ 30

Blade made by Phosphor bronze is characterized by the lowest friction among metallic types and avoids harming the roll of your product.

This material is also characterized with its high abrasion resistance.

■JIS Steel Grade (and equivalents)

PBP-3EH

Hardness: approx. Hs29

This specialized steel proves both high delicacy and hardness in blade, bluing high quality carbon steel.

The blade is finely sharp to bring high Doctoring effect.

■JIS Steel Grade (and equivalents)

SK85

Hardness: approx. Hs65

Ultra High Molecular Weight Polyethylene (UHMWPE) is elaborated in its high resistance to abrasion further exclusively for our blade development.

This type can go well with many kinds of rubber rolls including synthetic rubber and polyurethane rubber.

There are others, integrated with additives to elaborate its abrasion resistance, antistatic element, are also available.

Commercial name : UHMW-PE

Fiber Reinforced Plastics (FRP) blade is of epoxy resin in nature and laminated with glass fiber.

This type is versatile, adopting the grade which represents both high strength and abrasion resistance.

There are other options available, with additive to elaborate its thermostability, and with abrasives for more polished surface.

Commercial name: Glass Epoxy

Fiber blade laminated by carbon fiber instead of glass fiber.

This brings excellent Doctoring effect in various circumstances, utilizing strengths of fiber blade.

The content of carbon fiber in the blade can be customized between 25 ~ 100%.

Commercial name: Carbon Composite

Thanks to development in blade materials, we can offer more materials than listed here. Please consult us for details.